The art of crafting marimba soundboards is a delicate balance between science and tradition, with moisture content standing as one of the most critical yet often overlooked factors. Unlike mass-produced percussion instruments, high-end marimbas demand meticulous attention to the wood's internal equilibrium. The relationship between water molecules and cellulose fibers isn't merely about preventing cracks—it's about unlocking the instrument's soul.

In the rainforests of Honduras where premium rosewood grows, loggers have known for generations that freshly cut timber sings differently after seasonal drying. Modern luthiers have quantified this wisdom, recognizing that 8-12% moisture content allows the wood to vibrate with ideal elasticity. Too dry, and the timbre becomes brittle; too damp, and the notes lack projection. This narrow window separates a mediocre marimba from a concert hall masterpiece.

The seasoning process begins long before the wood reaches the workshop. Master suppliers monitor atmospheric conditions during air-drying, sometimes adjusting stockpile locations to account for microclimates. Kiln drying, while faster, risks case hardening that can deaden harmonics. The best makers employ hybrid approaches—six months of natural drying followed by controlled kiln sessions at temperatures low enough to preserve cellular structure.

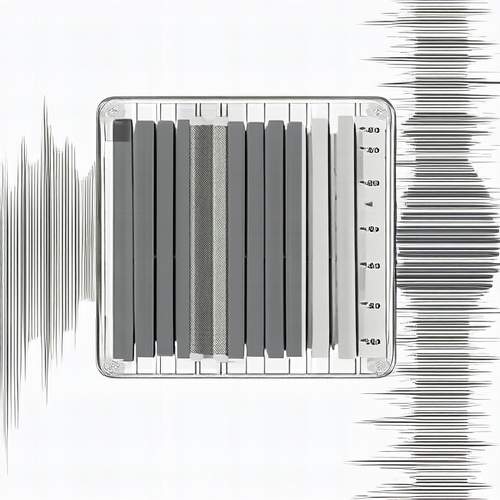

Seasoned wood tells its story through subtle cues. Craftsmen run their palms along planks to detect invisible moisture gradients; the faintest stickiness indicates areas needing further drying. Some workshops use ultrasonic testers, but veteran builders swear by the tap test—listening for the crystalline ring that signals perfect equilibrium. This tactile knowledge gets passed down through apprenticeships, impossible to fully document in textbooks.

Climate control continues throughout fabrication. Humidity-controlled rooms maintain 45-55% RH during tone bar carving, with workers monitoring hygrometers as diligently as tuning forks. The shaping process itself releases internal stresses, requiring intermittent resting periods where the wood rebalances. This explains why handmade marimbas take months to complete while factory models rush through in days.

Regional climate dictates post-assembly care. Instruments shipped to arid regions receive wax treatments to slow moisture loss, while those destined for tropical venues get oil finishes that resist swelling. The finest marimbas incorporate humidity sensors in their frames, allowing performers to monitor conditions during concerts. Some Japanese makers even embed thin bamboo strips that curl as natural hygrometers.

The pursuit of perfect moisture equilibrium reveals why vintage marimbas often sound superior. As wood ages over decades, its cellular structure achieves unprecedented stability. Modern accelerated aging techniques using vacuum chambers and frequency conditioning show promise, but time remains the ultimate artisan. This explains why conservatories treasure century-old instruments and why contemporary makers bury tone wood near termite mounds—an obscure technique believed to mimic decades of natural conditioning.

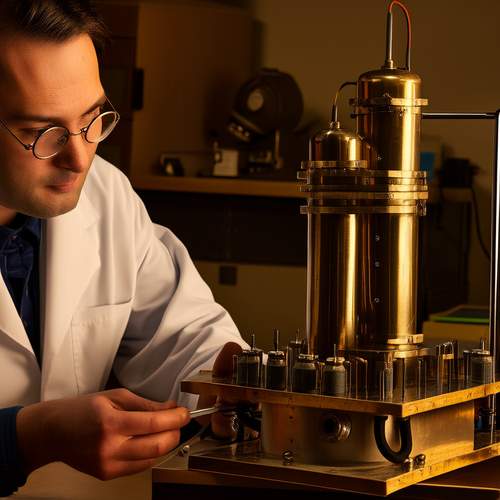

Recent breakthroughs in nano-cellulose research are rewriting traditional practices. Scientists discovered that moisture doesn't distribute uniformly at microscopic levels, explaining why two pieces with identical average moisture content can produce different tones. Some avant-garde builders now experiment with electromagnetic field conditioning to align cellulose fibers before carving.

At its core, moisture management in marimba soundboards isn't about restraining wood's natural tendencies, but guiding its transformation into a living resonator. The greatest instruments continue evolving long after leaving the workshop, their voices maturing as the wood dances with atmospheric changes. This dynamic relationship between artisan, material, and environment creates not just percussion instruments, but wooden symphonies waiting to be awakened by the right mallets.

By /May 30, 2025

By /May 30, 2025

By /May 30, 2025

By /May 30, 2025

By /May 30, 2025

By /May 30, 2025

By /May 30, 2025

By /May 30, 2025

By /May 30, 2025

By /May 30, 2025

By /May 30, 2025

By /May 30, 2025

By /May 30, 2025

By /May 30, 2025

By /May 30, 2025

By /May 30, 2025

By /May 30, 2025

By /May 30, 2025

By /May 30, 2025

By /May 30, 2025