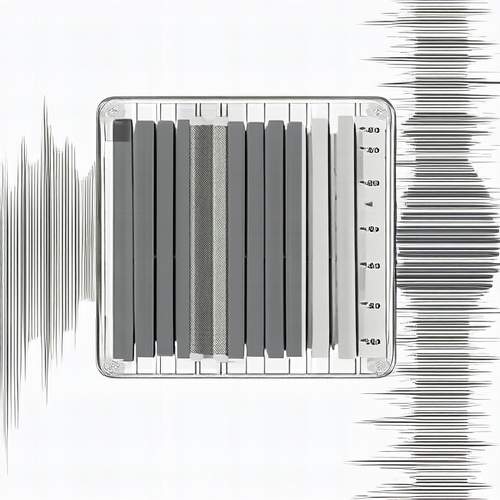

The relationship between reed thickness and pitch compensation in harmonicas remains one of the most nuanced yet underdiscussed aspects of instrument design. While most players focus on reed material or comb construction, the subtle variations in metal thickness fundamentally alter how a harmonica responds to bending, overblows, and even basic articulation. This isn't merely about manufacturing tolerances—it's an acoustic balancing act where thousandths of an inch determine whether a note sings or chokes.

Reed thickness doesn't exist in isolation. When a manufacturer increases thickness by 0.001", they're simultaneously affecting three critical parameters: the reed's stiffness, its mass distribution, and its vibrational decay characteristics. Thicker reeds generally produce brighter tones with faster attack, but the trade-off emerges in pitch stability—especially when air pressure changes during techniques like note bending. The myth that thicker reeds simply last longer fails to account for how they fundamentally change the instrument's voice and playability.

Pitch compensation becomes particularly crucial in chromatic harmonicas and low-tuned models. As reeds lengthen for lower notes, their thickness must be carefully tapered to maintain consistent responsiveness across octaves. Many premium harmonicas employ progressive thickness scaling—where higher octave reeds might be 0.045mm thick while bass reeds graduate to 0.085mm—but these measurements tell only half the story. The real artistry lies in how thickness interacts with reed curvature and slot clearance, creating what veteran technicians call "the sweet spot" where air efficiency meets tonal balance.

Modern harmonicas often suffer from what veteran players call "factory thickness syndrome"—a one-size-fits-all approach where reeds are cut to withstand manufacturing processes rather than optimized for musical performance. Hand-finished reeds from custom builders demonstrate the difference: by selectively thinning certain sections (particularly near the rivet end), they achieve both durability and nuanced pitch control. This explains why two harmonicas with identical measured thickness can behave completely differently under playing pressure.

The physics behind reed oscillation reveals why thickness affects pitch compensation so dramatically. When air flows through the reed plate, the reed doesn't simply vibrate up and down—it undergoes complex torsional movements that change with thickness. Thinner reeds exhibit more pronounced torsional harmonics, which can cause pitch to rise unexpectedly during hard playing. This phenomenon led to the development of tapered reeds in high-end harmonicas, where thickness decreases gradually from base to tip to control these parasitic oscillations.

Temperature introduces another layer of complexity. Brass—the most common reed material—expands with heat, effectively making reeds "thinner" in warm conditions. Players performing outdoors often notice their harmonicas going sharp in sunlight as the reed's thermal thinning increases its vibration frequency. Some custom builders now use composite materials with different thermal expansion properties specifically to combat this effect, particularly in harmonicas designed for stage use under hot lights.

Advanced players have developed thickness-based modification techniques that factories rarely employ. "Reed profiling"—the careful thinning of specific reed sections—can transform an ordinary harmonica's response. For instance, thinning the middle section of a draw reed while leaving the base thick creates a reed that bends more easily without sacrificing volume. These modifications require microscopic precision; removing just 0.02mm too much material can render the reed unusable. The best customizers work with dental tools and magnification to achieve these surgical adjustments.

Surprisingly, reed thickness affects different harmonica keys in unique ways. In higher keys (G, A), thicker reeds help control the naturally bright tone, while in lower keys (D, C), slightly thinner reeds prevent the sluggish response caused by increased mass. This key-specific thickness optimization explains why many professionals maintain separate harps for different musical keys rather than relying on pitch-shifting techniques. The difference in air requirements between a thick-reeded low F# and thin-reeded high G makes them feel like entirely different instruments.

The future of reed thickness engineering may lie in laser measurement and CNC machining. Several boutique manufacturers now use 3D scanning to map thickness variations across vintage reeds known for exceptional tone, then replicate these patterns with micron-level precision. This technological approach bridges the gap between the "black magic" of old-world craftsmanship and reproducible acoustic science. Early adopters report achieving vintage-style responsiveness without sacrificing modern durability—a holy grail in harmonica design.

Ultimately, reed thickness represents a compromise between durability and musicality that each player must navigate. While thicker reeds withstand aggressive playing, they often sacrifice the subtle pitch nuances that make harmonica such an expressive instrument. As players advance, many find themselves preferring slightly thinner reeds that "talk back" during complex techniques. This preference shift mirrors how violinists graduate from student-grade bows to more responsive concert models—proof that in harmonica as in all instruments, control ultimately matters more than brute strength.

By /May 30, 2025

By /May 30, 2025

By /May 30, 2025

By /May 30, 2025

By /May 30, 2025

By /May 30, 2025

By /May 30, 2025

By /May 30, 2025

By /May 30, 2025

By /May 30, 2025

By /May 30, 2025

By /May 30, 2025

By /May 30, 2025

By /May 30, 2025

By /May 30, 2025

By /May 30, 2025

By /May 30, 2025

By /May 30, 2025

By /May 30, 2025

By /May 30, 2025