The world of electronic drumming has undergone significant transformations over the past decade, with advancements in materials science playing a pivotal role in enhancing the player experience. Among these innovations, the rebound characteristics of silicone mesh heads have emerged as a critical factor in bridging the gap between acoustic and electronic drumming. Unlike traditional rubber pads, silicone mesh heads offer a dynamic response that closely mimics the feel of acoustic drumheads, making them a preferred choice for professional drummers and enthusiasts alike.

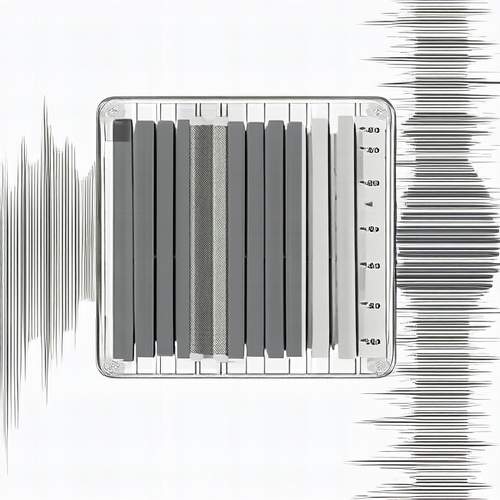

At the heart of this discussion lies the concept of rebound coefficient—a measure of how efficiently energy is returned to the stick upon impact. Silicone mesh heads excel in this regard due to their unique molecular structure, which allows for controlled energy dissipation and return. When a drumstick strikes the surface, the silicone mesh deforms slightly, absorbing the initial impact before springing back to its original shape. This action creates a responsive playing surface that reduces fatigue during extended sessions while maintaining the articulation required for complex patterns.

The manufacturing process of these silicone mesh heads involves precise engineering to achieve optimal rebound properties. Manufacturers carefully calibrate the thickness, tension, and weave density of the mesh to create different rebound characteristics suitable for various playing styles. Tighter weaves generally produce faster rebound, ideal for technical players who require quick stick return, while looser configurations offer more resistance, appealing to drummers seeking a feel closer to traditional mylar heads.

Climate conditions present an interesting challenge in maintaining consistent rebound performance. Unlike rubber pads that become harder in cold temperatures, silicone maintains its elasticity across a wider temperature range. However, humidity can affect the surface tension of silicone mesh heads, causing slight variations in rebound characteristics. Professional-grade electronic drums often incorporate environmental sensors that adjust trigger sensitivity to compensate for these changes, ensuring uniform response regardless of playing conditions.

Player technique interacts significantly with the rebound properties of silicone mesh heads. The angle of attack, striking velocity, and follow-through all influence how the energy transfers between stick and surface. Experienced drummers develop an intuitive understanding of this relationship, adjusting their playing dynamics to extract the desired response from the mesh. This nuanced interaction contributes to the expressive potential of electronic drum kits, allowing for subtle articulations that were previously difficult to achieve with older pad technologies.

Comparative studies between different generations of electronic drum pads reveal substantial improvements in rebound consistency. Early rubber pads suffered from "hot spots"—areas where the rebound characteristics varied noticeably across the playing surface. Modern silicone mesh heads demonstrate remarkable uniformity, with rebound coefficients varying by less than 5% across the entire striking area. This consistency enables drummers to develop reliable muscle memory, knowing that their sticks will respond predictably regardless of where they strike the head.

The relationship between rebound coefficient and sound generation in electronic drums represents another fascinating aspect. While the physical rebound affects the player's tactile feedback, the sensor technology underneath translates the impact into digital signals. Advanced triggering systems now account for rebound characteristics when generating sounds, creating more authentic velocity-to-volume relationships. This synergy between physical response and electronic sound production contributes significantly to the convincing acoustic emulation that modern electronic drums achieve.

Maintenance considerations for silicone mesh heads differ substantially from traditional drumheads. While they don't require tuning in the conventional sense, periodic cleaning and proper tension adjustment help maintain optimal rebound properties. Accumulated dust and skin oils can slightly alter the surface friction, affecting stick response. Manufacturers recommend using specialized cleaners that preserve the silicone's elasticity without causing degradation that could change the rebound characteristics over time.

The evolution of rebound characteristics in electronic drumming continues to push boundaries, with researchers experimenting with hybrid materials that combine silicone with other polymers to achieve specific response profiles. Some manufacturers are developing zone-specific rebound properties within single mesh heads, offering varying resistance across different areas to simulate the feel of different drum types. These innovations promise to further narrow the gap between electronic and acoustic drumming experiences, providing players with increasingly authentic and expressive playing surfaces.

As electronic drums become more prevalent in professional settings, the importance of well-engineered rebound characteristics cannot be overstated. The silicone mesh head represents more than just a technological improvement—it's a crucial interface that affects everything from basic playability to advanced expression. Drummers transitioning from acoustic kits often cite the rebound quality as the make-or-break factor in their adaptation to electronic instruments, underscoring how this seemingly technical specification profoundly impacts the musical experience.

By /May 30, 2025

By /May 30, 2025

By /May 30, 2025

By /May 30, 2025

By /May 30, 2025

By /May 30, 2025

By /May 30, 2025

By /May 30, 2025

By /May 30, 2025

By /May 30, 2025

By /May 30, 2025

By /May 30, 2025

By /May 30, 2025

By /May 30, 2025

By /May 30, 2025

By /May 30, 2025

By /May 30, 2025

By /May 30, 2025

By /May 30, 2025

By /May 30, 2025